ULTIFLEX DDSW

PRECISION DYE PACKAGE WINDER

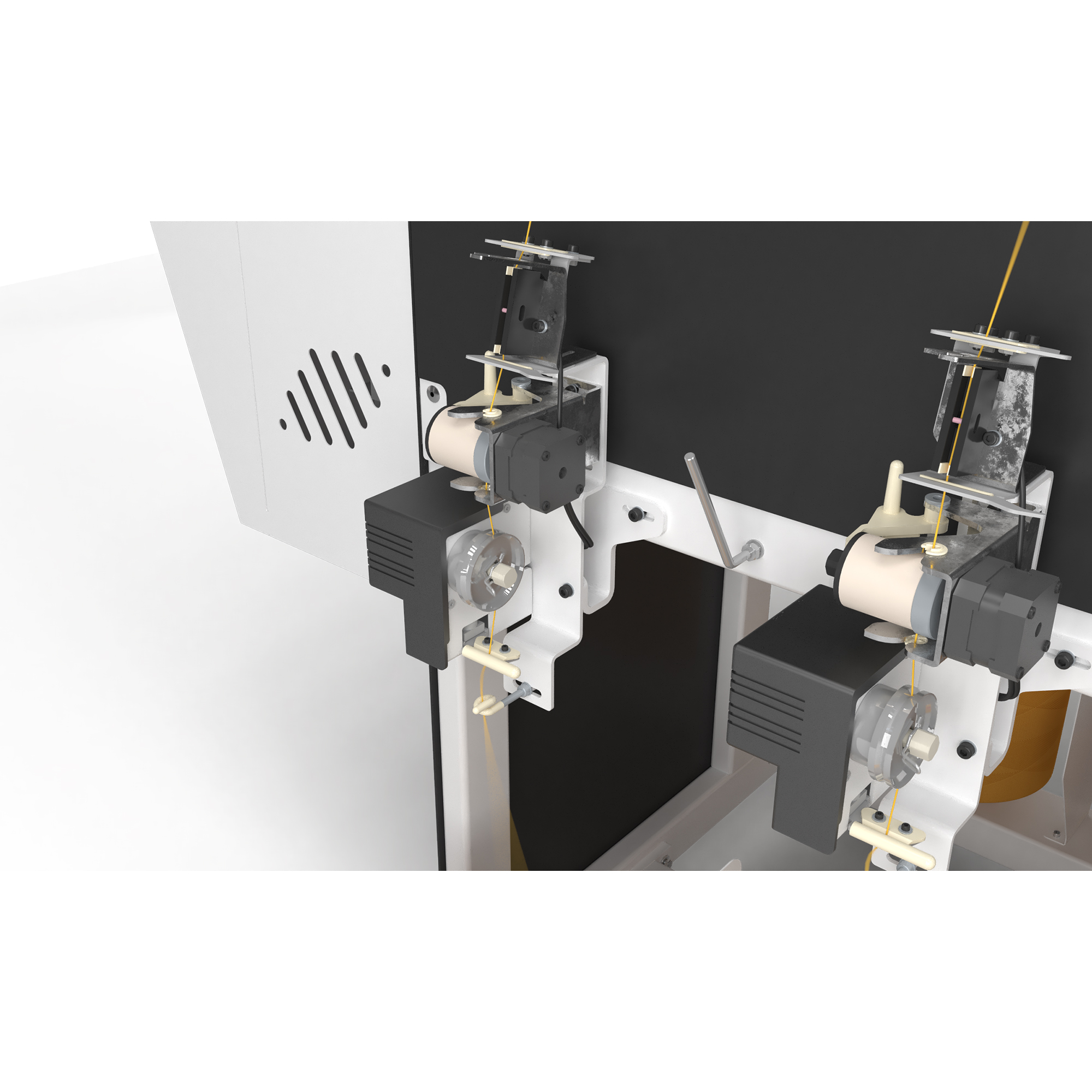

Ultiflex DDSW is a Precision Package winder designed for processing staple fibres or twisted filament yarn . It enables the production of Soft Dye packages with precisely controlled density , ensuring optimal dye penetration during the dyeing phase.

| Highlights |

|---|

| Modular Structure |

| Precision and Dynaflex Winding Technology |

| Counter Rotating Blades yarn laying system |

| Pneumatic Back Pressure System |

| Auto Tension Sytem |

| Touch Screen Industrial PC to control all Parameters |

| IoT ready |

| Technical Data | |

|---|---|

| Yarns Processed | Natural Fibre,Synthetic or Blended Staple Fibre All Kinds of Staple Yarns |

| Range of Count | From 1 to 250 Nm , 1 to 148 Ne |

| Working Process | Soft / Dye Packing suitable for HTHP yarn Dyeing |

| Winding Speed | Upto 1200 Mt/Min(Process Speed Depending on Process Parameter) |

| Installed Power | 400 W (Per Winding Unit) |

| Absorbed Power | 90 W |

| Take Up Arm | Double holder arms with adaptors and back pressure through electronic / pneumatic system.Driven by BLDC motor |

| Yarn Laying | Counter Rotating Blade Technology with adjustable blade for traverse lenghts.Driven by BLDC Motor |

| Take Up Tubes | Perforated-Cylindrical/Conical Tubes/SS Dye Spring |

| Tension System | Online close loop tension control with BTSR tension senser / open loop tension control with electronic disk tension device |

| Standard Configuration | Electric Over Feed Mechanism Yarn Presence Sensor , individual spindle yarn length,Diameter Setting and Measurement |

| Optional Devices | Automatic Doffing , Over Head Travelling Cleaner ,Splicer, Pre-Arrangement for Electronic Clearers Package, Transport Conveyor |

| Type of Winding | Step Precision/Precision/Random |

| Dimension(LxWxH) | 2360x1650x1655 |

ULTIFLEX DPSW

PRECISION SOFT / DYE PACKAGE WINDER

Reshmi’s new ULTIFLEX - DPSW is the Latest Modular Winding Platform available with two winding modes pricision and fix angle(Random).suitable to wind all Staple Fibres

| Technical Data | |

|---|---|

| Yarns Processed | Natural Fibre,Synthetic or Blended Staple Fibre All Kinds of Staple Yarns |

| Range of Count | From Ne 20 to 120 Ne |

| Working Process | Soft /Dye package winding suitable for HTHP yarn Dyeing |

| Winding Speed | Upto 1200 Mt/Min(Process Speed Depending on Process Parameter) |

| Installed Power | 370 W (Per Winding Unit) |

| Absorbed Power | 90 W |

| Take Up Arm | Double holder arms with adapoters and back presssure through electronic / pneumatic Sysytem |

| Yarn Laying | Counter Rotating Blade Technology with adjustable blades for traverse length |

| Take Up Tubes | Perforated-Cylindrical/Conical Tubes/SS Dye Spring |

| Tension System | Online close loop tension control with BTSR tension sensor / open loop tension control with electric disk tension device |

| Standard Configuration | Electric Over Feed Mechanism Yarn Presence Sensor Individual Spindle Yarn Length, Diameter Setting and Measurement |

| Optional Devices | Automatic Doffing , Over Head Travelling Cleaner ,Splicer, Pre-Arrangement for Electronic Clearers Package, Transport Conveyor |

| Type of Winding | Step Precision/Precision/Random |

| Dimension(LxWxH) | 2360x1650x1655 |

39 Series-DRSW

RANDOM WINDER- SOFT WINDING

39 Series DRSW are the most Economical and Efficient drum winders from Reshmi's range.The electronic grooved drum Machines are meant to process all type of staple fiber yarn.Desinged for winding speeds up to 1000 m/min, mechinical speeds up to 1400 m/min.

| Technical Data | |

|---|---|

| Yarns Type | Short and long - staple spun yarns made from natural and manmade fibre |

| Take up arm | Double Holder arms with adaptors and compact pressure system cradle |

| Size | 12 spindles minimum, 120 spindles maximum |

| Drive | Individual motor per spindle |

| Speed | Upto 1,200 m/min mechanical, practical speed according to the feed package |

| Take-up | i) Cylindrical packages upto 280 mm dia ii) SS Dye Spring iii)Perforated cheese iv) Multiflex cheese v) Perforated cone for HTHP yarn dyeing |

| Traverse | 6" standard (8"/10" optional) |

| Installed Power | 110 W per spindle |

| Consumed Power | 45 W per spindle |

| Tension System | Motorised tension device with adjustable disc tensioner |

| Shogging Motion Motor with gear box |

Available for individual section |

| Ribbon Breaker | Electronic |

| Length Control | Length setting and measurement available for individual spindle |

| Optional | Over head package Transportation Conveyor |

| Dimension | 2480x1050x2010 |

49 Series blends cutting edge technology with the simplicity and low maintenance advantages of traditional systems . 49 Series delivers uniform , high quality packages with optimal tension control - ideal for weaving , knitwear , hosiery and more.

| Highlights |

|---|

| Optimised Footprint |

| Individual Inverter Per Spindle |

| Automatic Tension Control |

| Pneumatic Back Pressure System |

| Brushless Motor Technology |

| Touch Screen Industrial PC to control all Parameters |

| IoT Ready |

| Technical Data | |

|---|---|

| Type of Winding | Random |

| Mechanical Speed | up to 1200 m/min |

| Drive | Individual |

| Yarn laying | Yarn laying with grooved drum |

| Package shape | Cylindrical or Cones |

| Take-up Tubes | Cylindrical or Cones upto 5'57' |

| Traverse | 152mm (6") |

| Take up package diameter | Up to 270mm |

| Yarns | Staple Yarns |

| Yarn count | Ne 3-120 |

| Number of spindles min/max | 16/128 |

| Installed Power | 125 W |

| Power consumption | 35-75 W |

74 Series DFRW

Precision Re-Winder

A perfect winder that benefits dye package winding filament yarns and helps enhance the customer to have a competitive advantage in the market, A highly effective precision winding technology that combines with the electronic tension gate system as a digitalized tension supported by the online BTSR closed-loop sensor system to control the tension of the yarn thereby providing perfect packages for dyeing, A highly cost-efficient winder that controls the yarn tension, especially for sewing threads, bright yarn, and filament yarns.

| Technical Data | |

|---|---|

| Type of Winding | Precision Winding / Electronic Winding |

| Mechanical Speed | Upto 1200 M/min (Process Speed Depends On Process Parameters) |

| Package Shape | Freely Programmable |

| Traverse Length | 30-250 Mm infinitely Variable |

| Package Diameter | 180mm - 230mm |

| Package Weight | Upto 4 kg (Depends On Yarn Type) |

| Supply Package Diameter | Upto 320 Mm |

| Yarn Types | Textured or Flat Filament, Elastic Yarns, Silk, Staple Yarns, Viscose and Twisted Yarns, Fine Technical Yarns |

| Take-Up Tubes | 0 Degree - 5 Degree 57 Minutes |

| Layout | Single Sided Machine |

| Spindles Per Section | 5 |

| Min/Max No, of Spindles | 5 Spindles / 60 Spindles |

| Gauge | 360mm |

| Drive | Individual Drive |

| Installed Power | 280 W Per Spindle |

| Consumed Power | 100 W Per Spindle |

| Winding Density | Freely Programmable |

| Tension | Electronic Gate Tension device Controlled by BTSR Sensor |

| Dimension | 1823x700x1550 mm |

39 Series-DRRW

RANDOM WINDER- REWINDING

39 Series are the most Economical and Efficient Drum winders from Reshmi’s range. The Electronic grooved drum Machines are meant to process all types of staple fiber yarns. Designed for winding speeds up to 1000 m/min, Mechanical Speeds up to 1400 m/min

| Technical Data | |

|---|---|

| Yarns Type | Short and long - staple spun yarns made from natural and Synthetic fibre |

| Take up arm | Double Holder arms with adaptors and compact pressure system cradle |

| Size | 12 spindles minimum, 120 spindles maximum |

| Drive | Individual motor per spindle |

| Creel | On-board,height adjustable |

| Speed | Upto 1,200 m/min mechanical, practical speed according to the feed package |

| Take-up Tubes | i) Cylindrical packages ii) Conical packages suitable for 3 deg 30 min,4 deg 20 min,5 deg 57 min, |

| Traverse | 6" standard (8"/10" optional) |

| Installed Power | 110 W per spindle |

| Consumed Power | 45 W per spindle |

| Tension System | Motorised tension device with adjustable disc tensioner |

| Shogging Motion Motor with gear box |

Available for individual section |

| Ribbon Breaker | Electronic |

| Length Control | Length setting and measurement available for individual spindle |

| Optional 1 | cheese winder(Roto Cone winders) |

| Optional 2 | CLASSIMATE EQUIPMENT:single slided-6 drums suitable for fixing classimate |

| Optional 3 | Over head package Transportation Conveyor |

| Dimension | 2480x1050x2010 |

All Rights Reserved @ Reshmi Industries