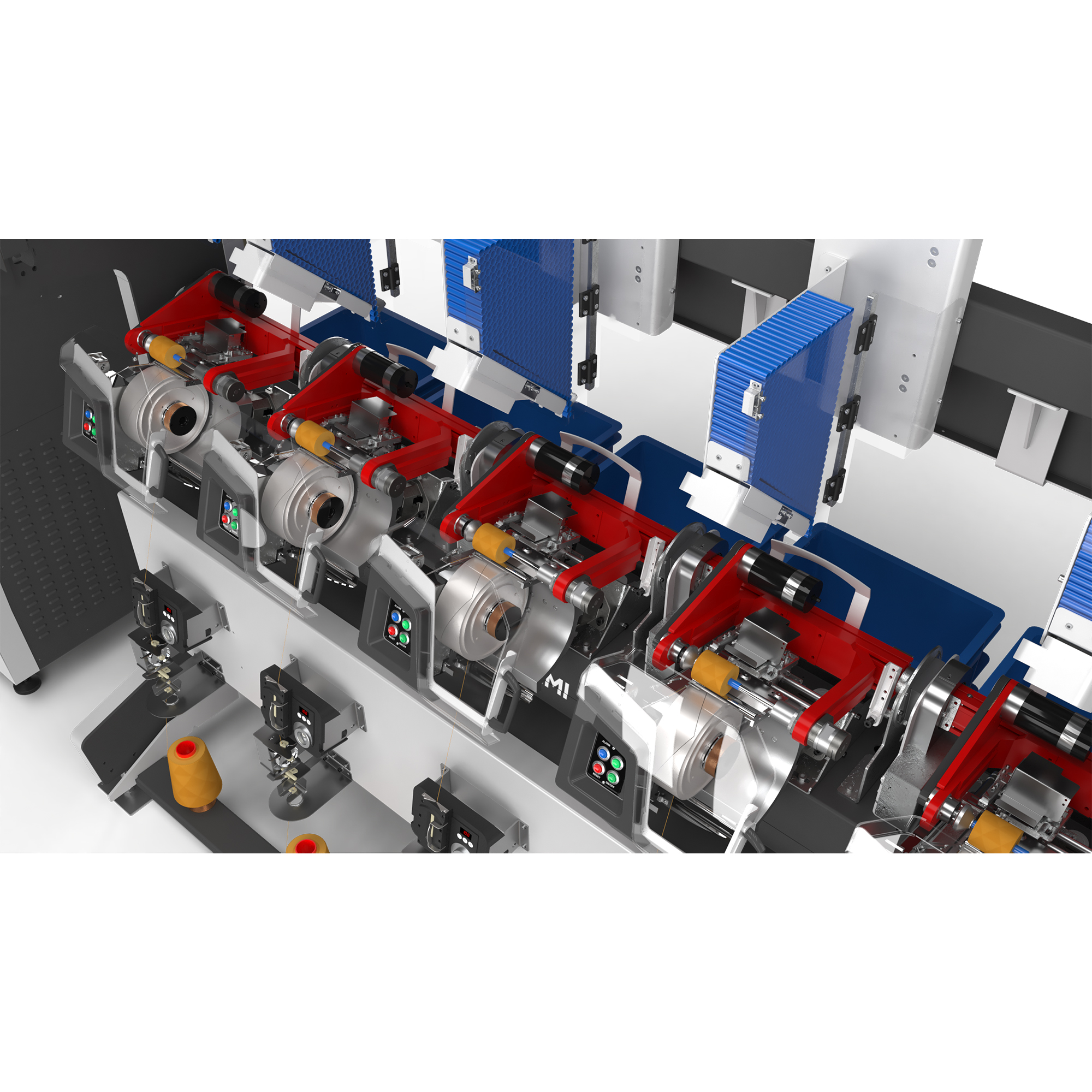

The Precithread PT2C is the latest high-speed automatic cone winder in the Precithread series, designed for superior efficiency and winding precision.

| Highlights |

|---|

| Working speeds upto 1250 Mpm |

| Shorter Doffing cycle under 15 secs |

| Advanced length measurement system |

| Standard Tuck- In device |

| Electro mechanical back pressure system for programmable back pressure |

| Precise lube applicator or Kiss Roller System available as options |

| IoT-ready for smart connectivity and performance monitoring |

| Optional Extended magazine |

| Technical Data - PT 2C | |

|---|---|

| Types of Winding | Precision Cross Wind |

| Mechnical Speed | Up to 1200 MPM Speed Depending Upon Process Parameters |

| Spindle Speed | Up to 1200 rpm |

| Package Shape | V Cone - 2 to 4 Degree |

| Traverse Length | 3.25" to 6" |

| Take up- Tubes | 1°30 up to 5°57 ; Tip Diameter 18 mm |

| Take up Package Diameter | Up to 120 mm |

| Supply Package Diameter | Up to 280 mm |

| Type of Yarn | Spun Thread/Cone Spun,Textured Filament, Heavy Industrial Sewing Thread of 1500 Denier |

| Count | Up to 3300 Dtex |

| Layout | Single sided Machine |

| No.of Spindles per Section | 5 |

| Min/Max No.of Spindles Per Machine | Any number(Due to Individual Control System) |

| Max no of Spindles per Oiling System | 20 |

| Gauge | 432 mm |

| Drive | Individual Dual Drive Servo System |

| Electronic Length Control | Micro Controller/PLC Based |

| Installed Power | 1.4KW(5 Spindles) |

| Compressed Air | 6 bar |

| Dimension(LxWxH) | 3079x767x2351 mm |

PRECITHREAD PT 2T

Automatic High-Performance Cop Winder

The Precithread PT2T is a Automatic high-performance cops winder, engineered for precision, speed, and superior yarn package quality

| Highlights |

|---|

| Working speeds upto 1250 Mpm |

| Shorter Doffing cycle under 15 secs |

| Advanced length measurement system |

| Standard Tuck- In device |

| Electro mechanical back pressure system for programmable back pressure |

| Precise lube applicator or Kiss Roller System available as options |

| IoT-ready for smart connectivity and performance monitoring |

| Technical Data-PT 2C | |

|---|---|

| Types of Winding | Precision Cross Wind |

| Mechnical Speed | Up to 1200 MPM Speed Depending Upon Process Parameters |

| Spindle Speed | Up to 1200 rpm |

| Package Shape | V Cone - 2 to 4 Degree |

| Traverse Length | 3.25" to 6" |

| Take up- Tubes | 1°30 up to 5°57 ; Tip Diameter 18 mm |

| Take up Package Diameter | Up to 120 mm |

| Supply Package Diameter | Up to 280 mm |

| Type of Yarn | Spun Thread/Cone Spun,Textured Filament, Heavy Industrial Sewing Thread of 1500 Denier |

| Count | Up to 3300 Dtex |

| Layout | Single sided Machine |

| No.of Spindles per Section | 5 |

| Min/Max No.of Spindles Per Machine | Any number(Due to Individual Control System) |

| Max no of Spindles per Oiling System | 20 |

| Gauge | 432 mm |

| Drive | Individual Dual Drive Servo System |

| Electronic Length Control | Micro Controller/PLC Based |

| Installed Power | 1.4KW(5 Spindles) |

| Compressed Air | 6 bar |

| Dimension(LxWxH) | 3079x767x2351 mm |

RCW-24TS (GW), RCW-24TS(TW)

Twin Spindle Cone Winding Machine/Cop Winding Machine

This Machine is used or Winding sewing thread yarns of all types. Precision Cone winding machine for Cone / Y Cone / Heavy Cop and Cheese.

| Technical Data | |

|---|---|

| Heat/Spindle | 12 heads / 2 Spindles per head |

| Traverse | 2" to 6" (Special Model - Above 6" to 10"), Fixed (to specified when working) |

| Machine Speed | 2800 RPM for Cotton and Polyster |

| Spindle Speed | Upto 666 m/min max (cotton & polyster - 333 m/min max).per head |

| Yarn Contact | Ceramic or hard chormium guide |

| Yarn Guiding / Layer | Cam Drive / Manual Adjusting |

| Cross Ratio | Change pulley |

| Lubrication | Trough or Waxing (Tension Bracket) Optional : Hot lube - Online Control |

| Motor | 190 W (0.25 HP) Motor / Head , 3 Phase ( Optional - Single Phase) |

| Production | 128 kg/12 Heads/ 8 Hours ( NE -40/2 Yarn) |

| Dimension(LxWxH) | 7200x760x1450 mm |

RTW - 12

Tube Winding Machine / Cop Winding Machine

This Machine is used or winding sewing thread yarns of cotton & synthetic yarn. Precision Cone winding machine for Tube / Y Cop / Heavy Cop

| Technical Data | |

|---|---|

| Spindles | 12 Spindles |

| No of Cops | 3 Cops Per Spindle (optional 4 Cops / 5 Cops) |

| Traverse | 2" Optional - 2 1/2", 3 1/4", 4" |

| Spindle Speed | 3000 rpm |

| Installed Electric Power | 0.25 Hp 3 Phase Motor / Head , 0.19 KW/Head (Optional - SIngle Phase) |

| Cross Ratio | Change pulley |

| Lubrication | Trough or Waxing (Tension Bracket) Optional : Hot lube - Online Control |

| Dimension(LxWxH) | 7200x760x1450 mm |

The precitube PT64-T is a unique sewing thread winder for small make ups on cylindrical tubes(cops).It combines state of the art drive technology with functionality and operational comfort of modern control concepts.with the achievable speed up to 10000 rmp it offers the highest production worldwide

| Technical Data | |

|---|---|

| Types of Winding | Precison Cross wind |

| Mechinical Speed | Up to 1000 NPM Process Speed Depending Upon Process Parameters |

| Package Speed | Cylindrical tubes(cops) |

| Traverse Length | 1.5" to 3"(76.2mm) |

| Take up-Tubes | Cylindrical,Maximum Length 64 mm |

| Take Up Package Diameter | Up to 43 mm |

| Supply Package Diameter | Up to 250 mm |

| Type of Yarn | Spun Thread/Cone Spun ,Textured Filament , Heavy Indusrial Sewing Thread of 1500 Denier |

| Count | Up to 1500 dtex |

| Layout | Single Sided Machine |

| No.of spindles per section | 1 |

| Min/Max No.of Spindlers per Meachine | 20 |

| Max no of Splndles per meachine | 20 |

| Gauge | 900 mm |

| Drive | Individual Dual drive Servo System |

| Electronic Length Control | Micro Controller/PLC Based |

| Installed Power | 0.75KW(1 Spindle) |

| Compressed Air | 6 bar |

| Dimension(LxWxH) | 861x807x1428 mm |